DISMANTLING

Before commencing to dismantle the pump, thoroughly clean the exterior and make a file mark

across the two flanges of the pump housing, as a guide when re-assembling.

Remove the six securing screws and separate the two halves of the main casting.

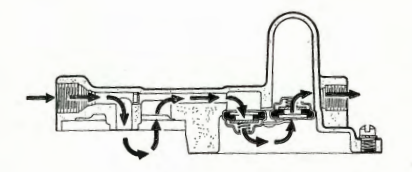

Turn the diaphragm, and pull rod assembly through an angle of 90°, when it may be disconnected from

its securing slot in the connecting link and withdrawn. Remove diaphragm spring.

Withdraw the valve retainer screws from inside the upper casting and remove the retainer plate, valve

assemblies, and valve retainer gasket.

On latest type pumps, valve retaining plates are omitted, the valve assemblies being a light tap fit

into the casting.

CLEANING AND INSPECTION OF PARTS

All pump parts must be thoroughly cleaned in order to ascertain their condition. Wash valves, upper castings, filters and other parts which come into

contact with the fuel in a clean paraffin bath separate from that used for dirtier components.

Upper and lower pump castings should be examined for cracks or damage. AC Repair Kits contain the items normally needed for fuel pump 'first aid' repair

and all of these should be used on each job, the corresponding worn parts being discarded.

RE-ASSEMBLY

Replace valve retainer gasket, valves, valve retainer, and secure in position with two retaining screws, or

tap new valves into recesses on latest pump types.

Replace filter gauze and cork seating gasket in position. Refit filter bowl.

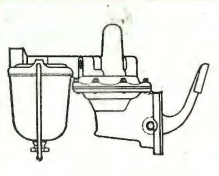

Place the diaphragm spring in position in the pump body. Place the diaphragm assembly over the spring

(the pump rod being downwards) and centre the upper end of the spring in the lower protector washer.

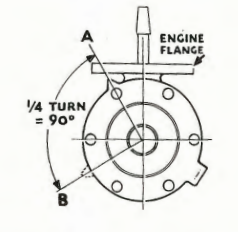

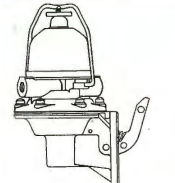

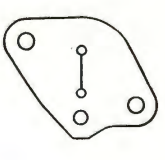

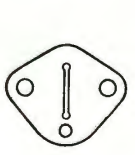

When fitting the diaphragm assembly the small locating tabs should be at position 'A' shown in the illustration. The diaphragm assembly should then

be pushed down until the flattened end of the pull rod enters the slot in the link and then turned a quarter

turn to the left until the diaphragm locating tabs are at

position 'B' and then they will be in line with the locating mark cast on pump body. The sub-assemblies of

the pump are now ready for fitting together, and this is carried out as follows:

Push the rocker arm towards the pump until the diaphragm is level with the body flanges.

Place the upper half of the pump into the proper position, as shown by the mark made on the flanges

before dismantling. Install the cover screws and spring washers and tighten until the heads of the

screws just engage the washers.

IMPORTANT

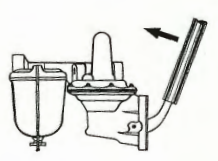

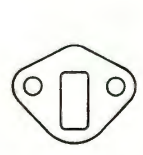

Before finally tightening the cover screws, the rocker arm must be held at its inward position

preferably using a short piece of tube as shown in the illustration. Sufficient pressure must be

exerted to draw the diaphragm inwards until its edges no longer protrude beyond the pump flanges.

While the rocker arm is so held, the cover screws should be securely tightened, working from side

to side so as to keep the pressure even.

Identification of Fuel Pump Types

Pipe Unions

Assembly Part No.

Comprising Union,

Nut and Sleeve |

PARTICULARS OF UNION |

Union Nut |

Pipe Sleeve

(if used) |

Remarks |

| Part Number |

Description |

Thread into Pump |

Thread for Union Nut |

| 114795 |

114626 |

1/4" Straight, for pipe sleeve |

1/8" x 27* |

7/16" x 24 |

114527 |

114628 |

|

| 114796 |

114629 |

5/16" Straight, for pipe sleeve |

1/8" x 27* |

1/2" x 24 |

1524190 |

114631 |

|

| 114797 |

114633 |

5/16" Elbow, for pipe sleeve |

1/8" x 27* |

1/2" x 24 |

1524190 |

114631 |

|

| 114798 |

114632 |

1/4" Elbow, for pipe sleeve |

1/8" x 27* |

7/16" x 24 |

114627 |

114628 |

|

|

856810 |

5/16" Straight, for soldered nipple |

1/8" x 27* |

1/4" Gas |

|

|

Uses Washer 851011 |

|

1524114 |

5/16" Straight, for soldered nipple |

1/2" x 20 |

1/4" Gas |

|

|

Uses Washer 855136 |

|

1524730 |

1/4" Straight, for pipe sleeve |

1/2" x 20 |

7/16" x 24 |

114627 |

114628 |

Conical seat, in pump |

|

1524729 |

5/16" Straight, for pipe sleeve |

1/2" x 20 |

1/2" x 24 |

1524190 |

114631 |

Conical seat, in pump |

|

1524328 |

1/4" Straight, for flared pipe |

1/2" x 20 |

7/16" x 24 |

|

|

Uses Washer 855136 |

|

1524322 |

5/16" Banjo, for pipe sleeve |

1/2" x 20 |

1/2" x 24 |

1524190 |

114631 |

Also uses -

Bolt 1524323

Washer 855136 (2)

|

| * N.P.T.F. |

1524555 |

1/4" Banjo, for pipe sleeve |

1/2" x 20 |

7/16" x 24 |

114627 |

114628 |

Ditto |

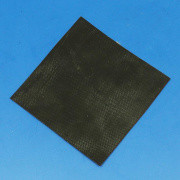

Engine Pad Gaskets

While every care has been taken in the compilation of this publication, no responsibility can be accepted for any inaccuracies which may have arisen.